The Significance of Mechanical Design in Product Development

Takeaways: Mechanical design is pivotal in product development as it bridges the gap between conceptual ideas and tangible products. It enhances functionality, promotes innovation, and ensures manufacturability. Understanding the significance of mechanical design can lead to more efficient processes, reduced costs, and successful end products.

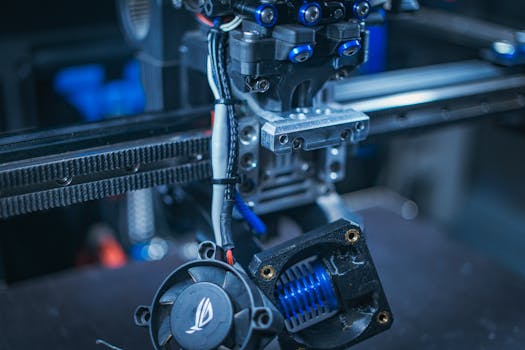

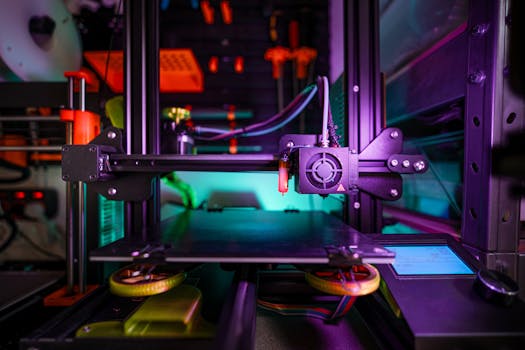

Mechanical design plays a critical role in the entire product development process. It encompasses the creation and optimization of mechanical systems and components, ensuring that they meet both functional and aesthetic requirements. In today’s competitive market, the importance of mechanical design cannot be overstated. This article delves into the significance of mechanical design in product development, examining its various stages, benefits, and impact on overall project success.

Understanding Mechanical Design

- Conceptualization: This initial phase focuses on brainstorming ideas and defining the product’s purpose.

- Detailing: Engineers create detailed drawings and specifications for each component of the product.

- Prototyping: A prototype is developed to test the design’s functionality, aesthetics, and manufacturability.

- Testing: The prototype undergoes rigorous testing to identify any flaws or areas for improvement.

- Final Design: After testing and revisions, the final design is prepared for manufacturing.

These stages highlight the iterative nature of mechanical design, where feedback from each phase informs improvements and refinements.

The Benefits of Mechanical Design in Product Development

- Enhanced Functionality: Well-thought-out mechanical designs ensure that products perform their intended functions efficiently. This is crucial for user satisfaction and product reliability.

- Cost Efficiency: By optimizing designs for manufacturability, companies can reduce material waste and production costs. This strategic approach leads to better profit margins.

- Improved Time-to-Market: A streamlined mechanical design process can significantly cut down on development times, allowing companies to launch products faster.

- Innovation and Creativity: Mechanical design encourages innovative approaches to problem-solving, leading to unique and competitive products.

- Compliance and Safety: Mechanical designers ensure that products meet regulatory standards and safety requirements, reducing the risk of liability issues.

The integration of advanced technologies, such as Computer-Aided Design (CAD) software, further enhances these benefits. CAD allows for precise modeling, simulation, and analysis, enabling designers to visualize and test their ideas before committing to production.

Challenges in Mechanical Design

- Complexity: As products become more complex, the mechanical design must accommodate various interactions between components, which can be challenging to manage.

- Material Selection: Choosing the right materials for the desired performance, weight, and cost can be difficult and requires careful consideration.

- Balancing Aesthetics and Function: Designers must ensure that products are not only functional but also appealing to consumers, which can sometimes be at odds with practical design choices.

- Collaboration: Effective communication between design, engineering, and manufacturing teams is essential to avoid misunderstandings and ensure that the final product meets all requirements.

Addressing these challenges requires a skilled team of engineers, designers, and project managers who can work collaboratively to achieve the best outcomes.

Conclusion