Troubleshooting Common Mechanical Failures: A Comprehensive Guide

Takeaways: In this article, we will cover the most common mechanical failures that can occur in machinery and equipment, along with practical troubleshooting methods. Understanding these issues can save you time and money by allowing you to diagnose and resolve problems efficiently.

Mechanical failures can occur in various types of equipment, from household appliances to industrial machines. Knowing how to recognize these issues and troubleshoot them effectively is crucial for maintaining performance and preventing costly repairs. This guide will explore some of the most common mechanical failures and provide detailed troubleshooting steps to help you address these problems.

Understanding Common Mechanical Failures

- Overheating: This occurs when a machine runs at an excessive temperature, potentially leading to component failure.

- Vibration: Unusual vibrations can indicate misalignment, imbalance, or worn bearings.

- Noise: Unusual sounds, such as grinding or squeaking, can signal mechanical issues.

- Leaking fluids: Fluid leaks can indicate seal wear or damage and can lead to more significant problems if not addressed.

- Electrical failures: Electrical issues can cause machinery to stop working entirely and may range from simple blown fuses to complex circuit failures.

Troubleshooting Steps for Common Mechanical Failures

1. Identify the Symptoms

Begin by observing the machine and identifying any symptoms. Take note of:

- When the problem occurs (e.g., during startup, operation, or shutdown).

- The specific sounds or vibrations you notice.

- Any unusual smells or leaks.

Documenting these observations can help you determine the root cause of the failure.

2. Consult the Manual

Refer to the equipment’s manual for troubleshooting guidance. Many manuals include sections on common issues and recommended solutions. This will provide you with a framework to understand the machine’s normal operation and potential failure points.

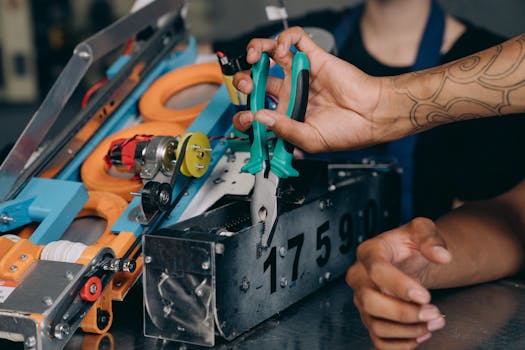

3. Check for Obvious Issues

Perform a visual inspection of the equipment. Look for:

- Loose or damaged components.

- Signs of wear on belts, bearings, and seals.

- Fluid leaks or pooling.

If you notice any obvious problems, address them first as they may be the cause of the failure.

4. Run Diagnostic Tests

If the issue isn’t immediately apparent, consider running diagnostic tests. Many modern machines come equipped with self-diagnostic capabilities. Use these features to check for error codes or alerts that can pinpoint the issue.

5. Consult with Experts

If you are unable to resolve the issue, consult with a professional technician. They can provide insights based on their expertise and may have access to specialized tools for diagnosing complex problems.

Preventing Mechanical Failures

- Regular Maintenance: Schedule routine maintenance checks to keep your equipment running smoothly.

- Proper Usage: Ensure that all operators are trained to use the machinery correctly to prevent misuse that can lead to failures.

- Monitoring: Implement monitoring systems to track machine performance and detect issues before they become major problems.

Conclusion